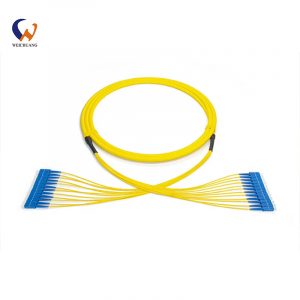

Fiber optic tactical cable is a high-performance, high-strength fiber cable designed for demanding environments where network stability and durability are essential. As it is characterized by a simple structure, lightweight, and strong practicality, the fiber optic tactical cable has been commonly used in applications fields such as telecommunications, fiber access networks, base stations and other situations where reliable, rugged, and high-speed data transmission is critical. Also, fiber optic tactical cable can be supported by both single mode and multi-mode, depending on specific application requirements. Tactical optical fiber cable, with its rugged construction, which provides excellent tensile and compressive strength, makes it suitable for both short-term and long-term deployments.Applications

Fiber optic communication system、fiber access network、LAN、RRU-BBU equipment、base station, ect.

Index

1.IL≤0.3dB(with repeatability).

2.RL:SM APC≥60dB,SM UPC≥50dB,MM≥30dB.

3.Temperature range:-40℃~+80℃.

4.Insertion times>1000.

5.Tensile 0~15Kg.

The high performance, durability, and reliability of fiber optic tactical cables are inseparable from their robust internal and external construction. It is composed of 6 different materials: fiber core, aramid fiber (kevlar) strength members, inner jacket, water blocking layer, armored layer, outer jacket. These components collectively enhance the operational performance of the tactical fiber optic cord.

The fiber core in the tactical fiber optic cable line mainly transmits optical signals with high efficiency and minimal loss, ensuring high-speed data transmission over long distances.

Aramid Fiber (Kevlar) Strength Members is essential in Fiber Optic Tactical Cable as it needs to Enhance the cable's tensile strength, protecting the fiber core from mechanical stresses such as pulling and twisting during installation and use.

The inner jacket itself serves to protect the tactical fiber optic cable’s integrity, providing an extra layer of defense against physical damage and environmental factors.

The water-blocking layer protects the tactical fiber optic cable from getting wet or operating in humid environments, preventing moisture from reaching the fiber core and causing it to stop working.

The Armored layer protects the Fiber Optic Tactical Cable from external impacts, crushing, and rodent damage, making it suitable for harsh outdoor environments.

The Outer jacket is mainly used to protect tactical fiber cable from environmental factors such as ultraviolet radiation, chemicals, and physical wear, ensuring the lifespan and reliability of the cables under various conditions.

Anti-Bending Technology: The tactical optical fiber cable specializes in anti-bending, providing greater bandwidth and enhancing network transmission characteristics.

Parallel Reinforcement: Regarding the two parallel reinforcement parts, they help the fiber optic tactical cable with good compression resistance and protect the optical fiber.

Practical Design: The outdoor leather wire of the fiber optic tactical cable has a simple and unique groove design, is lightweight, and offers strong practicality, making it easy to install and maintain.

Temperature Stability: The tactical fiber optic cable can operate stably in a wide range of temperatures, from -40°C to 80°C, making it suitable for various environmental conditions.

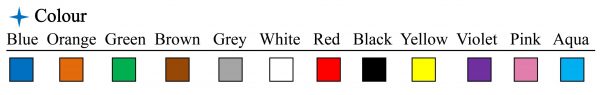

Custom Service: We offer a selection of over 12 custom colors for our fiber optic tactical cable, ensuring our products are perfectly tailored to your unique requirements.

1.Provide fiber connection from 12cores to144cores.

2.Using 4、8、12、24cores of MPO connectors, reduce the failure and reduce wiring space.

3.Upgrade from 10G to 40G、100G network transmission, and support the transmission of 100G delay index.

4.According to user’s configuration requirement, Can choose multimode fiber(OM 3、OM 4) and single mode fiber (G652D、G657A 2) and other fiber type.

5.Using circle、small diameter fiber cable to realize smaller bending radius, and make storage and laying convenient and fast.

6.The protect tube of the dust-proof、pressure-resistant、tension-resistant can effective protect fiber cable and connectors from damaging during transportation and installation.

1.Good versatility and interchangeability,stable and reliable connection,high repeatability.

2.Low insertion loss,high return loss.

3.Simple wiring,small space.