Copyright © 2023 SIHONG WEICHUANG OPTICS CO.,LTD, All rights reserved.

This is where you can browse products in this store.

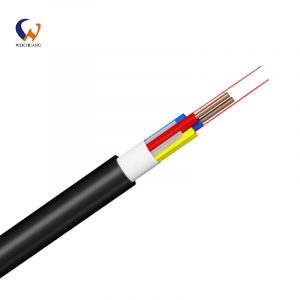

1.Special low-bend sensitivity fiber provides high bandwidth and excellent communication transmission property.

2.Two parallel strength members ensure good performance of crush resistance to protect the fiber.

3.Simple structure,light weight and high practicability.

4.Novel flute design, easily strip and splice, simplify the installation and maintenance.

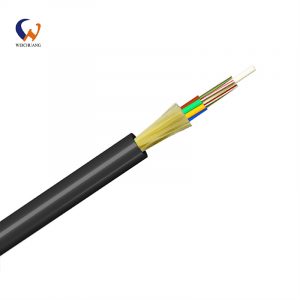

Element: tight buffer fiber,used 6,12 core distribution cable for the Subunit into a compact, then used wrap winding the cable is completed with outer jacket. The cable inclue 4,6,8,12 sub-cables, the every Sub-cables.the every sub-cable include 6,12 tight buffer fiber.

Element: Simplex cable are stranded around the non-metallic central strength member.

1.Sheath mechanical and physics performance content correlative standard request.

2.Diameter and bending radius small, lt can installation freely in narrow room.have both optical signal transmission and electricity transmission.

1.600μm tight buffer fiber,steel tube protect reinforcing steel-wire,braiding(aramid yarn) , flame retardant jacket High indentation strength.High tensile strength gopher or protected,small diameter, flexibility and easy bend.

2.Excellent stripping performance of tight buffer fiber.

3.Suited to SM fiber and MM fiber(50um and 62.5μm).

4.It is ideal for fiber optic temperature transmission project.

Element: Simplex cable are stranded around the non-metallic central strength member

1.Good mechanical and thermal performance.

2.Steel wire as the central strength member.

3.Hydrolysis resistant loose tube.

4.Tube filling compound ensures critical protection of fiber.

5.Specially designed stranded structure eliminating contraction of tubes.

6.Rugged, durable PE jacket protects against UV radiation, fungus etc.

7.Water-blocking measures :

- Loose tube gel-filled

- 100% cable filling compound

- Corrugated steel tape(CST) enhancing moisture-proof

1.Great mechanical and temperature performance.

2.High strength loose tube that is hydrolysis resistant.

3.Special tube filling compound to make surea critical protection of fiber.

4.Good crush ability and soft.

5.Adopt the measures below to assure the water-proof function.

6.Single non-metallic central strength member.

7.Special tube filling compound ensure a critical protection of fiber.

8.Fully fiber filled.

1. 900μm Or 600 μm tight buffer fiber.aramid yarn,soft flame-retardant jacket.

2. Excellent Stripping performance of tight buffer fiber.

3. Suited to SM fiber and MM fiber (50μm and 62.5μm).